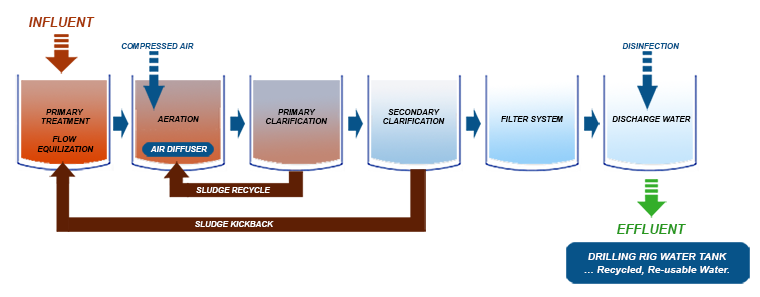

With the growing problem of Wastewater disposal in the oil field, Basin Wastewater Solutions (BWS) has the answer. By treating the waste on site in our state of the art portable treatment plants, we can turn your unusable waste into valuable rig water. This process would not only help with the never-ending need of water on site but would also take a heavy burden off the local municipalities wastewater treatment plants. Our portable unit is housed inside an insulated 45' C-box, and is totally self-sufficient. This system would allow you to eliminate the need of the existing waste storage containers on site thus increasing valuable space on the pad. This would also eliminate the need for waste pumping trucks on location twice a week. The amount of waste that is pumped into our unit will be processed and filtered through a specialized membrane turning the waste into effluent (water). This water will then be able to be used on the rig for numerous things such as drilling and boiler water. Levels of the treated water will have a BOD count of less than 5 mg/L and TSS count of less 1 mg/L.

Our unit has a 5,000 gallon fresh water holding system. The drilling company can use their preferred vendor to fill this tank as needed. BWS has a pressurized water delivery system to get the water to all of the housing units on location.

This unit will be able to handle 2,000 gallons of sewage a day although it is estimated that the average site would only produce 1,000 gallons a day. This leaves plenty of room for changing conditions and not putting the unit at the edge of its capabilities. The loss of fluid through treatment is next to zero, meaning that if you put 1,000 gallons of waste in, you get 1,000 gallons of water out. Our unit also has computer monitoring integrated into its system so that we can control and keep an eye on the unit no matter our location. This computer system will also notify us if something has gone wrong and needs servicing.

The benefits of treating waste on site rather than dealing with it the conventional way are:

1. Approximately 1/5 the footprint of conventional tanks, increasing valuable space on the pad.

2. The water produced is yours to use. Reducing the amount of new water hauled into the rig therefore saving you thousands of dollars.

3. No more sewage hauling trucks and less water trucks bringing water on site thus creating a safer work area and less travel of roads.

4. Conventional system of multiple holding tanks is no longer needed, saving the oil company money.

5. Eliminating extra sewage on local municipalities showing the state you are environmentally conscious.

BWS is a company that wants to stay small enough to give our clients good quality care. This means we as owners will be on-site often and very "hands-on". On the other hand we are also large enough to provide reliable service for multiple rig sites

.